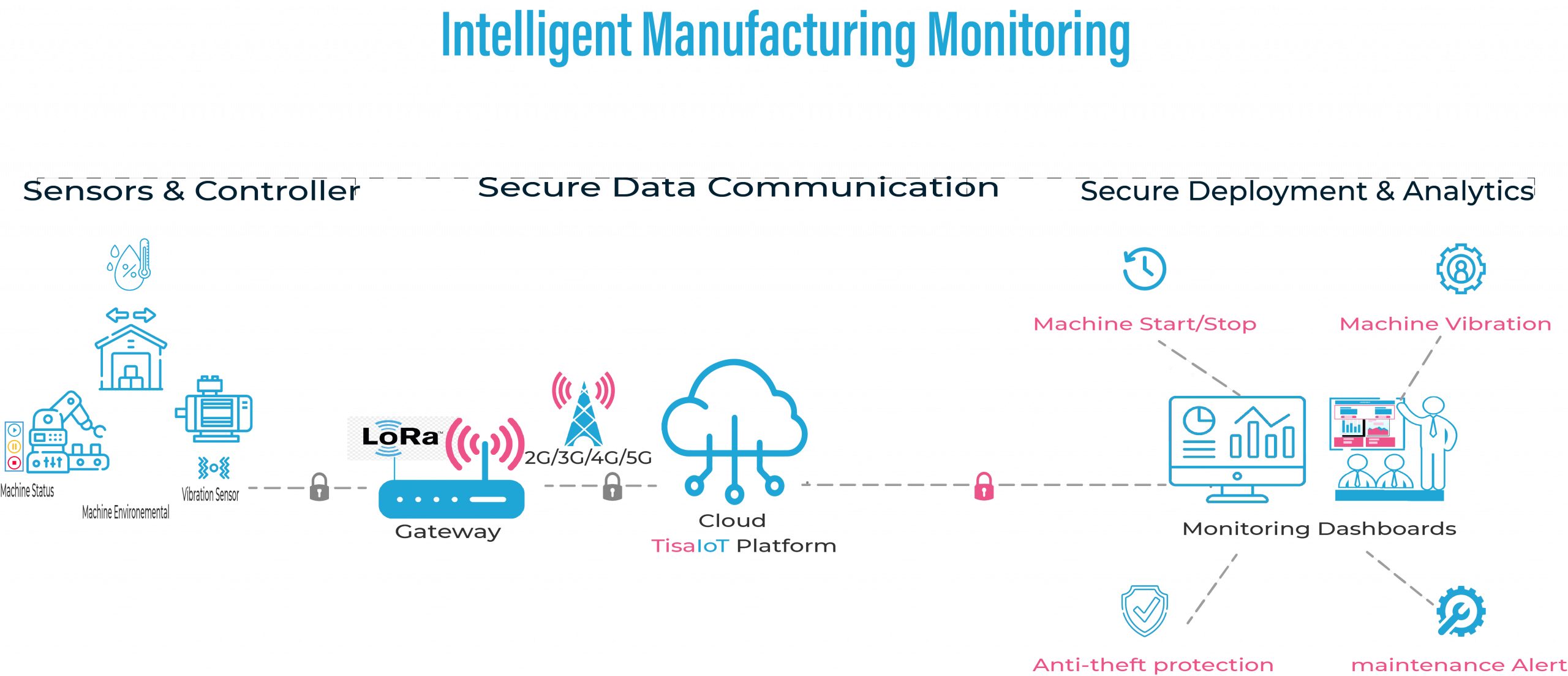

Smart Manufacturing

In the current trend toward digitalization, manufacturers increasingly rely on a range of technology platforms to help streamline and accelerate their production processes. Artificial Intelligence (AI), data analytics, or Digital Twin (DT) tools are more and more deployed. Organizations aim at a better understanding and usage of Industrial Internet of Things (IIoT) data. In general, data generated by IIoT devices can provide companies with deep insights enabling them to build products faster and more effectively. However, the difficulty resides in the integration of these technologies: often companies struggle with capitalizing on the information they have gathered. A future-proof network in which Information Technology (IT) and Operational Technology (OT) are fully connected and secured to the highest standards allows you to manufacture faster and cheaper than your competitors. It is the backbone of industrial improvements like edge computing, predictive maintenance, remote commissioning, DigitalTwin and advanced analytics.

Asset condition monitoring:

Asset condition monitoring keeps equipment in good shape through predictive maintenance, while preventing over-maintenance and the premature replacement of parts. This not only optimizes operations and ensures facilities are not experiencing downtime due to insufficient maintenance, but also allows manufacturers to keep machines running for a longer period.